A yacht falls off the hook during discharge from a ship, a mobile home comes loose from its rigging while being slewed above trees, a machine is damaged during lifting at a port terminal. All of these damage claims have been handled recently by our surveyors. It is understood that expensive goods falling from a height of several metres result in complex claims and excessive costs. It is not uncommon for only a total loss to be attested in such cases.

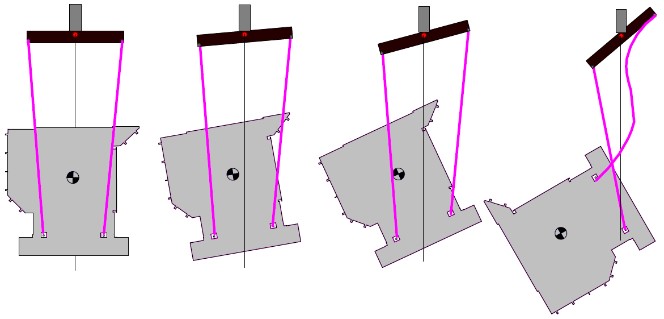

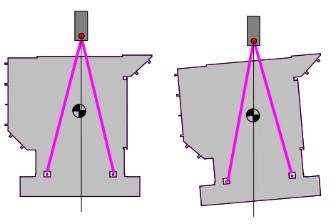

One example of a lifting error was the rigging of an unsuitable lifting arrangement to a heat exchanger for loading at the port. An "unstable square" was created under a non-stabilised H-crossbeam. This turned the whole lifting operation into a case of balancing an egg on the back of a spoon. Damage to the heat exchanger was inevitable. The damage could have been avoided if a "stable triangle" had been created between hook and cargo by rigging a suitable lifting arrangement.

The following two sketches illustrate the case of the “unstable square” versus the “stable triangle”:

Wrong

Correct

Manufacturers can help to minimise the likelihood of damage, for example by considering the placement of suitable lifting eyes during the design phase or by issuing a lifting plan for a proper arrangement of the gear. However, such measures will not always be effective as conditions and the lifting gear available at different locations will vary.

The biggest problem from our point of view and based on what we have learnt from experience is that the personnel on site are often unaware of even the minimum technical standards to ensure safe loading and/or lifting. Time and again this results in damage to the cargo and risks for the personnel involved.

There are several international regulations for lifting operations, such as the rules laid down by the German Association of Occupational Accident Insurance Funds (DGUV) or the British Lifting Operations and Lifting Equipment Regulations (LOLER). They stipulate minimum standards for lifting operations and are enforced to ensure compliance. Suggesting to the insurance industry to take steps to enforce these existing regulations more emphatically and to have the personnel of crane companies, terminals, and other logistics service providers trained in order to be able to implement these minimum standards may prove to be a promising idea. For example, there are online training courses on the regulations that can be provided quickly and at a manageable cost to sensitise staff to the risks and dangers.

Lifting Operations and Lifting Equipment Regulations (LOLER) (hse.gov.uk)